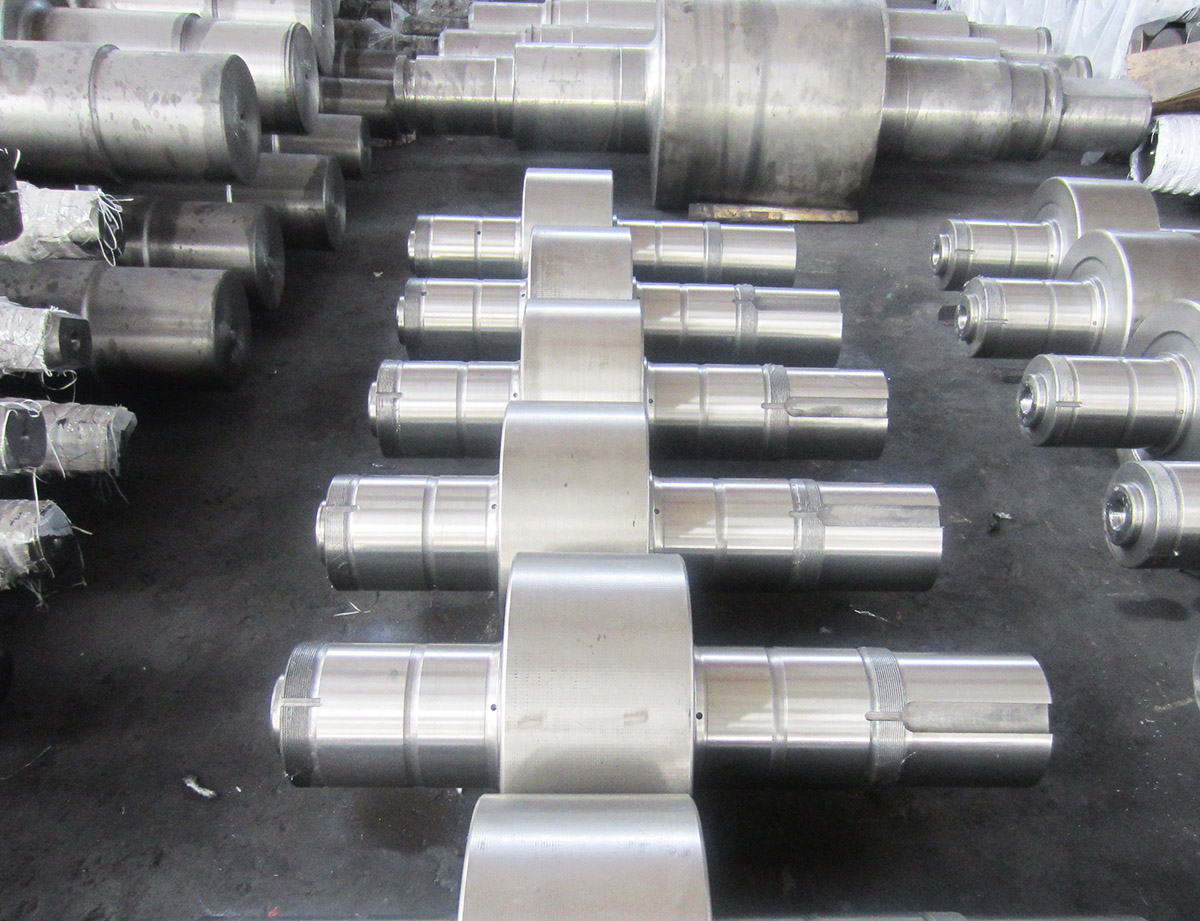

Centrifugal infinite cold hard roll

Alloy infinite chilled cast iron rolling mill has a long service life. Usually applied to the intermediate and finishing mill stands of long and flat product hot rolling mills. Usually, ICDp rollers add chemical compositions such as Cr, Ni, and Mo, which may increase the depth of the working layer. There are a large number of carbon compounds in the roller body matrix structure, which have good wear resistance. The advantages of ICDP rolling mill include high hardness, reduced hardness, good fire resistance, and ease of heat treatment process. This is why it is widely used around the world. The hardness of the application varies: for strip mills, the hardness of the rolls is usually 75-85HS, while for medium and thick plate mills, the hardness is relatively small, at 70-80HS

Parameter details

Chemical Composition%

| Model | Carbon | Silicon | Manganese | Chromium | Nickel | Molybdenum | Vanadium |

| IC | 2.90-3.60 | 0.60-1.20 | 0.40-1.20 | 0.60-1.20 | 0.20-0.60 | ||

| ICⅠ | 2.90-3.60 | 0.60-1.20 | 0.40-1.20 | 0.70-1.20 | 0.50-1.00 | 0.20-0.60 | |

| ICⅡ | 2.90-3.60 | 0.60-1.20 | 0.40-1.20 | 0.70-1.20 | 1.01-2.00 | 0.20-0.60 | |

| ICⅢ | 2.90-3.60 | 0.60-1.20 | 0.40-1.20 | 0.70-1.20 | 2.01-3.00 | 0.20-0.60 | |

| ICIV | 2.90-3.60 | 0.60-1.50 | 0.40-1.20 | 1.00-2.00 | 3.01-4.80 | 0.20-1.00 | |

| ICV | 2.90-3.60 | 0.60-1.50 | 0.40-1.20 | 1.00-2.00 | 3.01-4.80 | 0.20-2.00 | 0.20-2.00 |

Advantages and Applications

| Model | hardness HS | Tensile strength MPa | Size MM | Unit mass KGS | Application |

| IC | 50-70 | ≥160 | Φ300-1000 | Rolls for intermediate and finishing stands of section steel mills, bar mills, hot-rolled strip mills | |

| ICⅠ | 55-72 | ≥160 | |||

| ICⅡ | 55-72 | ≥160 | |||

| ICⅢ | 65-83 | ≥350 | 500-30000 | ||

| ICIV | 70-83 | ≥350 | |||

| ICV | 77-85 | ≥350 | Working rolls for medium and thick plate mills, hot-rolled strip mills, working rolls, and leveling rolls |