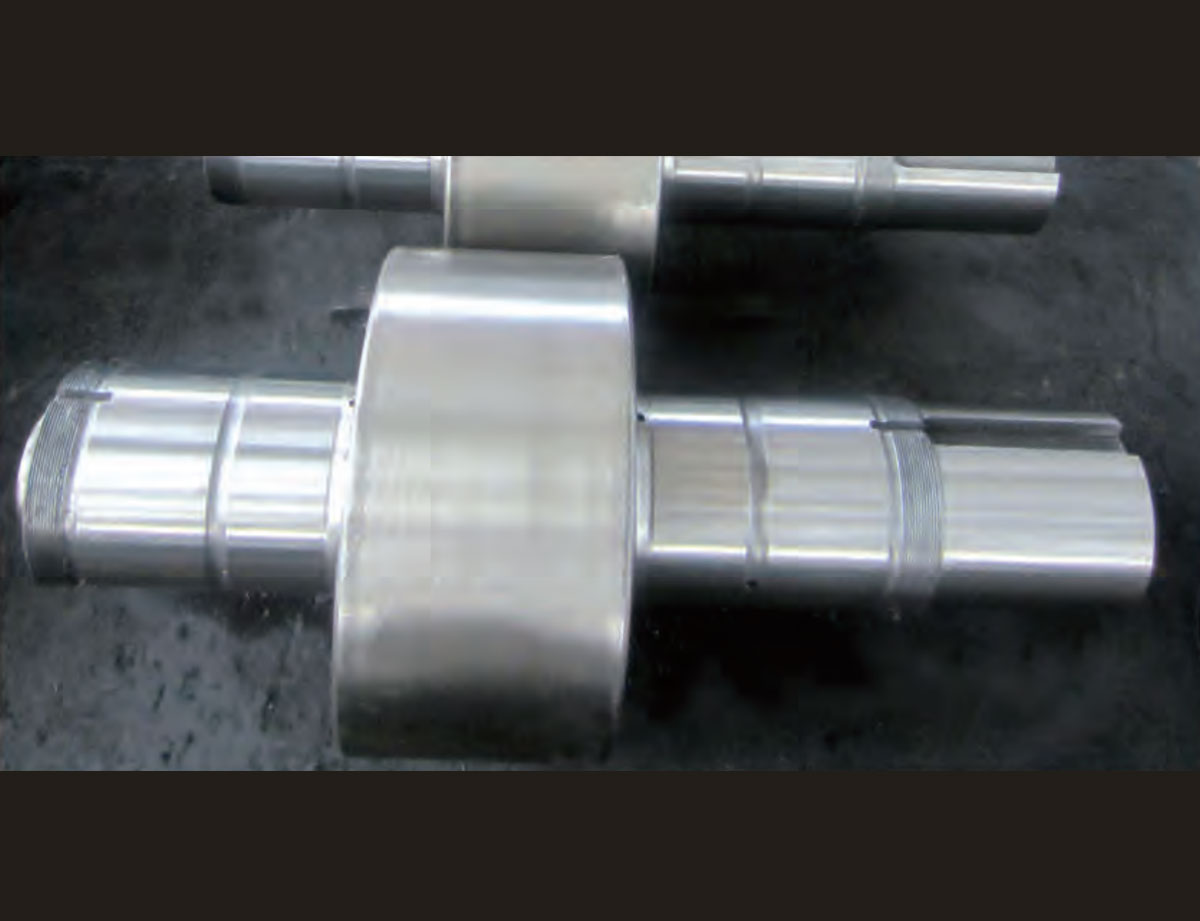

Edger roll

Cold iron rolling mill is a type of cast iron rolling mill, whose working layer matrix contains almost no free ferrite. They have hardness and excellent wear resistance, suitable for precision machining of light rod and wire mills and narrow strip steel mill stands. Its organization consists of small pearlite and carbides.

Parameter details

Chemical Composition%

| Model | Carbon | Silicon | Manganese | Chromium | Nickel | Molybdenum |

| CCⅠ | 2.90-3.60 | 0.25-0.80 | 0.20-1.00 | 0.20-0.60 | 0.50-1.00 | 0.20-0.60 |

| CCⅡ | 2.90-3.60 | 0.25-0.80 | 0.20-1.00 | 0.30-1.20 | 1.01-2.00 | 0.20-0.60 |

| CCⅢ | 2.90-3.60 | 0.25-0.80 | 0.20-1.00 | 0.50-1.50 | 2.01-3.00 | 0.20-0.60 |

| CCIV | 2.90-3.60 | 0.25-0.80 | 0.20-1.00 | 0.50-1.70 | 3.01-4.50 | 0.20-0.60 |

Advantages and Applications

| Model | hardness HS | Tensile strength MPa | Bending strength MPa | Application |

| ICⅠ | 60-70 | ≥150 | 300-400 | Rolls for small profile mills, bar and wire mills, and hot-rolled narrow strip steel finishing stands Milling machine |

| ICⅡ | 62-75 | ≥150 | 300-400 | |

| ICⅢ | 65-80 | ≥350 | 500-700 | |

| CCIV | 70-85 | ≥350 | 500-700 |